Industrial mufflers are engineered to reduce noise from engines, compressors, blowers, and other equipment operating under pulsating or continuous gas flow. These mufflers are available in reactive, resonator, and combination designs—providing targeted attenuation of low-frequency tones and harmonics, as well as broadband sound energy.

Designed for high-pressure, high-temperature, and contaminated flow environments, industrial mufflers can be configured for both inlet and discharge applications. They are used extensively in compressor systems, vacuum exhaust, engine-driven equipment, and pneumatic conveying operations.

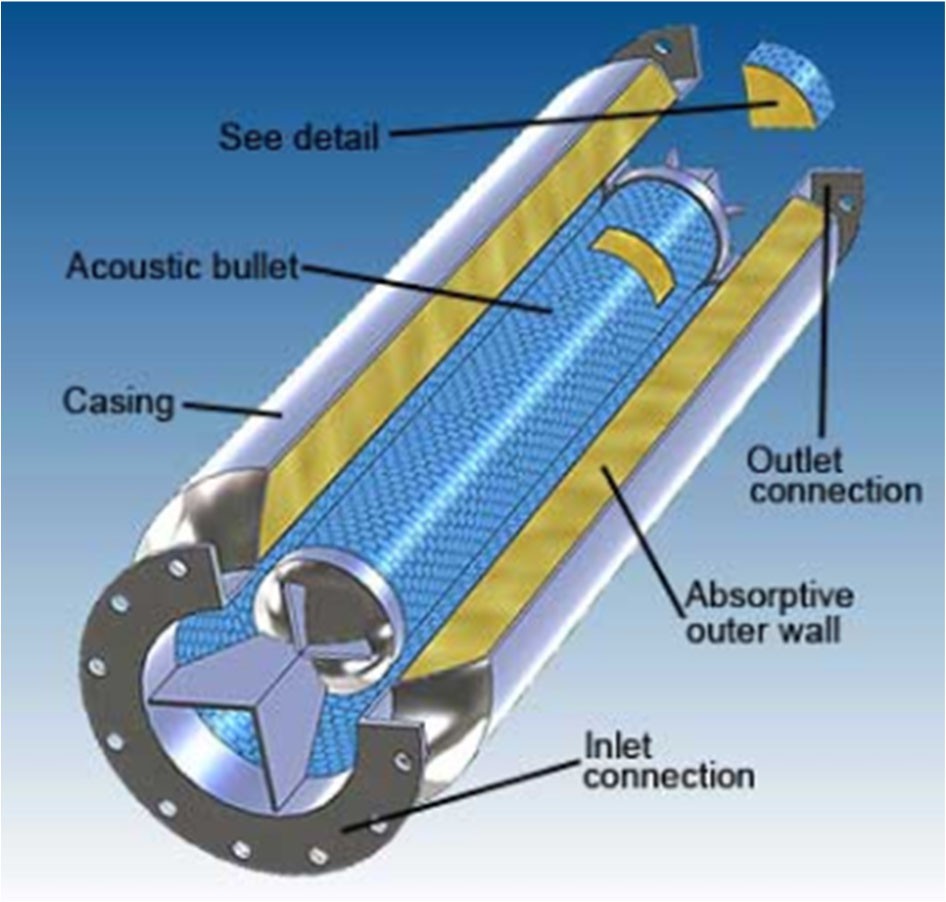

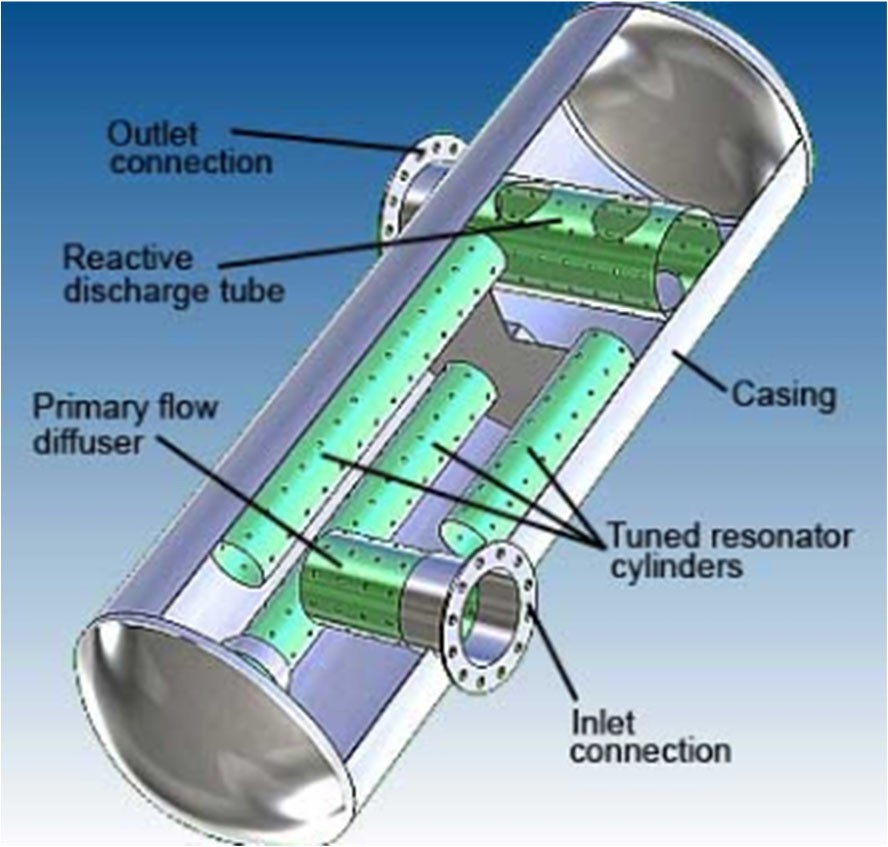

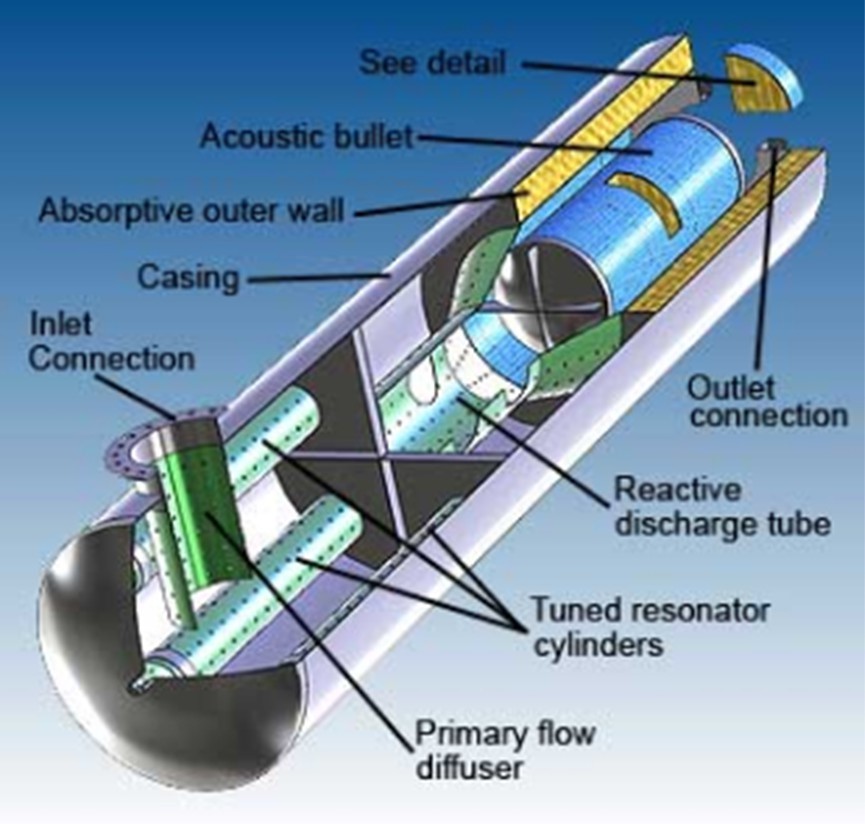

Available in cylindrical configurations, these mufflers are constructed from heavy-duty welded steel, with internal geometries

tuned to deliver performance while maintaining low back pressure and flow efficiency.

Tuned Low-Frequency Attenuation

Reactive chambers and resonator tubes cancel dominant tones and harmonics associated with pulsating flow.

Broadband Noise Reduction

Optional absorptive fill materials address mid- to high-frequency turbulence and exhaust noise.

Compressor-Ready Performance

Proven in reciprocating and screw compressor installations—both for air and process gases.

All-Welded Industrial Construction

Fabricated from carbon steel or stainless steel with corrosion- resistant coatings and optional weather protection.

Custom Inlet and Discharge Configurations

Horizontal or vertical mounting, end or side ports, and customizable

flanged or threaded connections

Reciprocating and rotary screw compressors Vacuum pump discharge and intake silencers Diesel and natural gas engine exhaust Pneumatic conveying and bulk material systems High-pressure air and gas blowers

Oil C gas, chemical, power generation, and industrial facilities

Industrial mufflers use acoustic tuning and flow modeling to provide maximum insertion loss while minimizing system impact. Chamber sizes, resonator lengths, and media type are selected based on system frequency content, flow characteristics, and installation constraints.

At Ochoa Industries, we provide custom design solutions for industrial and marine applications. Our specialties include ventilation, noise control, and explosion-proof air conditioning, focusing on performance and safety.

Copyright © 2025 Ochoa Industries, All rights reserved.